Jabin College Library Info

Alrighty folks, let's dive into the hot topic of why our fellow NRIs are trading in their Starbucks for masala chai back in India. Haha, jokes apart, the reasons are as diverse as a Bollywood dance number! Firstly, the lure of the booming Indian economy is like a siren song to those entrepreneurial spirited NRIs. Secondly, the charisma of family and cultural roots is as potent as a grandma's secret curry recipe. And lastly, the pursuit of a comfortable lifestyle combined with familiar traditions is more tempting than a plate of samosas! So, there you have it, the appealing mix of economic opportunities, cultural ties, and a balanced lifestyle is making NRIs pack their bags and book flights to India faster than you can say "Bollywood"!

Read More

Yes, it is indeed possible to download the Times of India daily ePaper. This newspaper offers its readers the convenience of reading the news online, with an option to download the paper for offline reading. You can access it through their official website or via their app, which is available on multiple platforms. This service may require a subscription. It's a handy option for those who prefer digital reading and want to stay updated with the news on-the-go.

Read More

College life in India is a unique blend of academic rigor, cultural diversity, and vibrant extracurricular activities. It opens up a world of opportunities for personal and professional growth, offering a broad spectrum of subjects and disciplines to choose from. It's also a time of self-discovery, independence, and making lifelong friendships. Despite the academic stress, there's plenty of enjoyment, as campuses are filled with festivals, events, and sports. In essence, it's a transformative journey that shapes one's future.

Read More

The cost of buying a research paper in India can vary greatly based on several factors. These include the complexity of the topic, the length of the paper, and the urgency of the deadline. On average, it could range from 500 to 2,000 INR per page. However, while cost is a significant factor, it's also important to consider the credibility and quality of the source. Remember, buying papers may seem convenient, but it's always best to do your own research and learning.

Read More

This topic is quite delicate, as it delves into personal choices and cultural nuances. It's not about which is better or worse, marrying a foreign girl or an Indian girl, it's more about compatibility, mutual respect and understanding. Each individual is unique, regardless of their nationality, and the success of a marriage largely depends on shared values, goals and personal chemistry. It's essential to remember that it's not about the nationality but the person you are marrying. Always prioritize love, respect and mutual growth over stereotypes and misconceptions.

Read More

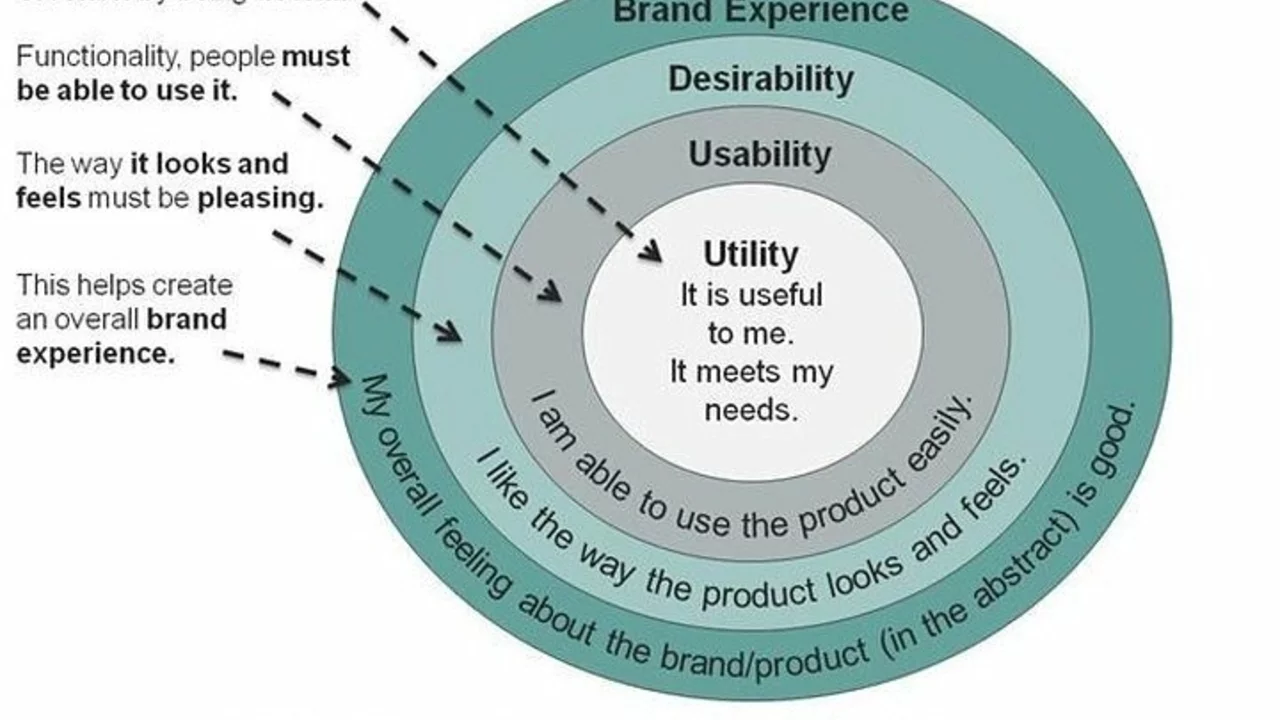

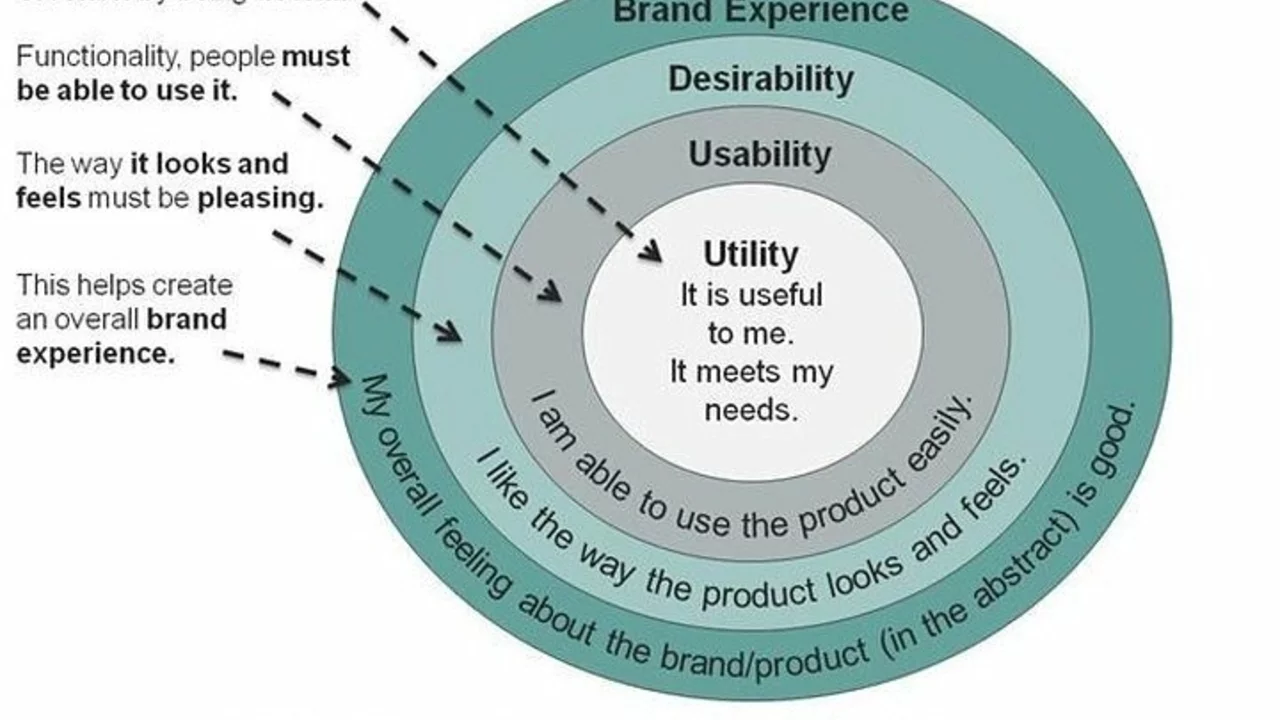

In my experience, the Times of India website leaves much to be desired. The primary issue seems to be the overwhelming number of ads, which cause the website to load slowly and disrupt the reading experience. Furthermore, the site's layout is cluttered, making it difficult to locate specific articles or information. Lastly, the quality of the content itself often lacks depth and credibility. In summary, the combination of excessive ads, poor design, and subpar content contribute to a less-than-ideal user experience on the Times of India site.

Read More

Marriage brings significant changes in one's life, from shared responsibilities to the shift in personal priorities. You start making decisions jointly, considering your partner's views and feelings. It's a transition from a self-oriented lifestyle to a life of compromise and mutual understanding. The dynamics of your social life also change as you adjust to a new family. Ultimately, marriage offers a chance to grow together, fostering deep companionship and shared experiences.

Read More

In my quest to find the best Indian news app for Android, I've tested several popular choices. After weighing the pros and cons, I've found that the top contenders include Dailyhunt, Inshorts, and Times of India. Each of these apps offers a user-friendly interface, a wide range of news categories, and customizable settings. However, my personal favorite is Dailyhunt, as it provides local language support and a vast collection of news sources. Ultimately, the best app for you may vary depending on your preferences and needs, so I recommend giving these options a try to find the perfect fit.

Read More

In the future, choosing between living in India or the USA might be a tough decision. Both countries offer unique opportunities and challenges. India is projected to have a booming economy and a young, dynamic workforce, while the USA has a strong education system and a diverse cultural landscape. Personally, I think it would depend on individual priorities and goals. Ultimately, both India and the USA have a lot to offer, and it's up to each person to decide which country aligns better with their aspirations.

Read More

The Redmi Note 11 Pro is a new budget phone from Xiaomi, released in India in 2021. It comes with a 6.67-inch FHD+ AMOLED display, a Snapdragon 732G processor, a 5,000 mAh battery, and a quad rear camera setup. The phone also supports 5G and has a fast charging system. It offers a good experience with its high-end features and affordable price point. Overall, the Redmi Note 11 Pro is a great choice for budget-conscious consumers in India.

Read More